Professional Painting Preparation Services

We have a vast network of professionals spanning the entire country, so your location is not an issue. Our 50 years of experience gives us unique insight into working on structure in different environmental and industrial settings. We know what works where.

Preparing a surface before you start working on it is as important as the painting process itself. Walls, especially in commercial settings, are covered with dirt and impurities from the environment. Some of these compounds are corrosive and would compromise the durability of the paint job. Failure to remove them would make new coating wear off faster than it should. Worse, you would end up spending more on frequent repaint jobs. Painting preparation costs more and adds a few extra days to your project. However, the long-term benefits are hard to pass up. The paint job will last at least twice as long, reducing the number of times you need a redo.

At Commercial Painting USA, we are dedicated to providing efficiency to our clients. Even as we give you high-quality services, we understand the need to save your hard-earned cash. You must get value for every penny spent. That is why we can guarantee professional paint preparation services as part of our industrial painting package. The preparation process is relatively standard for most industrial painting projects. Still, it is crucial to assess a structure to determine its individual needs.

Here are some of the factors crucial in this process

Cleaning to Remove Surface Contaminants

Superficial contaminants found on a structure come from environmental exposure. They include dust, rust, and corrosive chemical compounds. Old paint should also be removed from the surface, especially when working on industrial buildings. Chemicals produced during the manufacturing process sip into these surfaces and contaminate them.

It is important to remove them before applying a fresh coat of paint. They may reduce the adhesiveness of the new paint coat, making it peel off soon after application. Some impurities also corrode the new coating from the inside out. Different techniques are used depending on the surface. We use abrasive blasting to clean commercial surfaces before painting. This method uses pressurized air and granular particles directed onto the surface to remove superficial compounds. It is effective as it reveals the original surface of the building. Abrasive blasting leaves smooth surfaces that adhere well to the new paint.

Protection for Equipment and Personnel

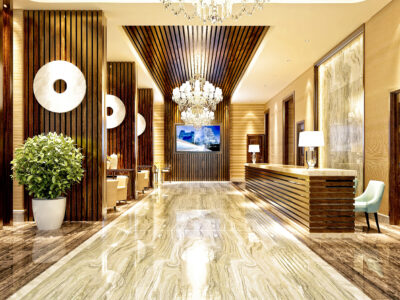

Any industrial setting will have some valuable equipment and furniture that is exposed during the painting process. When working with us, you do not have to evacuate your facility for fear of damaging this equipment. We will take utmost care to leave everything as we found it regardless of the surface we are working on. Before we even start cleaning, we move anything fragile from the space and cover up the rest with water and dustproof materials. We also cover surfaces that do need working on, such as floors, to keep them clean.

Additionally, we always observe safety requirements when preparing a structure for painting. Since we use powerful machines and chemical compounds, there is an increased risk of injury. Protective gear to keep particles produced by the process from the body is provided to all personnel on-site.

Surface repairs

A surface may need more than some cleaning and primer before the fresh coat of paint is applied. After cleaning, we evaluate a surface to look for any signs of physical deterioration that may need repairs. Our team includes professionals who understand construction and will use appropriate techniques to locate and redo damaged surfaces. They include chippings and cracks, water-damaged surfaces, and dents. Abrasive blasting removes all coatings from a surface. Some structures need waterproofing of anti-corrosive coating to improve their functionality. Resurfacing may be required to apply sealants and other protective coatings. Repairing a structure makes the final paint job smooth and flawless. It also cuts the time used by making the surface even, and hence, easy to work on.

Priming the surface

Commercial painting professionals know that priming is crucial. It could mean the difference between a durable paint job and one that calls for a redo in just a few months. Different types of primers are used in industrial painting projects. The environment of the facility determines the best kind depending on external climatic conditions and internal processes. Common factors to consider when selecting a primer include the following;

- The humidity in the facility

- pH levels

- Temperature

- Susceptibility of the surface to rust

Different kinds of paint also pair well with specific primers. For instance, primer used for silicone paint is different than that used with waterproof paint for exterior surfaces. The primer helps the paint adhere better to the surface, protects the structure, and ensures a smooth finish. The type of the surface also matters. There are different primers for concrete, metal, and floors. It is important to work with professionals that understand these variables as it saves you plenty of heartache in the future.

Commercial Painting USA has a team of professional painters and consultants for this kind of task. We first assess your structure and weigh this against your project specifications to determine what is required. We will then advise you on the best course of action and source all the materials you need for the project.

The Bottom Line

Surface preparation is an important aspect of commercial painting projects. The benefits include

- Saving money

- Improving the integrity of the structure

- Extending the lifespan of a structure

- Increasing the durability of the paint job

- Ensuring a flawless and desirable end product

This process may increase the time needed to complete your project, but it is well worth it. Selecting the right contractor to deliver these benefits to you is a key ingredient to success. Commercial Painting USA is your reliable partner in all paint-related matters, including surface preparation. Your satisfaction is our priority and the reason why we are committed to providing quality services at all times. Do not miss out on these amazing offers. Contact us today via phone or email for any inquiries to set up an appointment or a price quote.